Aluminium, Zamak or injection-moulded plastic after all?

Sometimes a choice of material is very simple, while at others subtle factors make all the difference. Discover Teledyne FLIR’s story. They decided to exchange their TrafiCam traffic camera’s plastic housing for an aluminium version. They had and still have multiple good reasons for that decision.

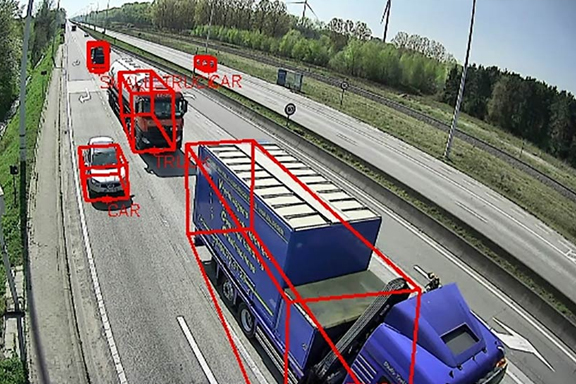

TrafiCam traffic cameras monitor traffic flows to be able to control the traffic lights. That makes them important tools to ensure a smooth, safe flow of traffic. Teledyne FLIR’s cameras can be found around the world in many different climates and weather conditions. They must withstand harsh sunlight, or at other times, rainfall and wind, occasionally mixed with sand or salt from their surroundings.

When the TrafiCam’s original plastic housing proved prone to cracks, Pedeo helped redesign a new aluminium version. Aluminium is better in extreme weather conditions. Its mechanical strength is greater, it can withstand exposure to sunlight and is not vulnerable to creep. Ageing will not result in cracking or deformation.

Strength and safety; in some applications opting for aluminium or Zamak is a no-brainer. Machines for financial transactions in public locations are one example. Housings used in this sector must be proof against multi-day security testing, vandalism and physical challenges. Teledyne FLIR’s solutions also attract vandalism at times. Thanks to their new housing, they are now assured of optimal protection.

A desire for strength and durability was the initial reason to contact Pedeo. During the design phase, however, other benefits soon revealed themselves.

As well as physical protection, aluminium can also provide electromagnetic shielding of electronic components. That makes separate shielding unnecessary, as this property is already naturally present.

All mounts and threads can be incorporated directly into the high-pressure casting. That means there’s no more need for inserts or transitions between different materials. This immediately eliminated several of the previous housing’s weaknesses.

Furthermore, the entire housing acts as a cooling block, collecting heat generated by the electronics and dissipating it by means of air channels between slender aluminium vanes. It’s a great example of how the right material and a well-thought-out design can reinforce each other.

The housing also received an additional coating of paint. The gorgeous black finish further improves the resistance to corrosion and sunlight, the darker hue optimises heat dissipation and the cameras still look good as new, even after years of use.

Aluminium and Zamak provide a sturdy, yet elegant look and feel. While this may seem subjective, practice shows that these materials are seen to indicate luxury, reliability and durability. Thanks to the new housing, the cameras look well-maintained at all times. As well as actually being sturdy and dependable, their appearance conveys these properties too. In this way, their presence on the streets helps contribute to accountability.

With the new housing, the cameras last much longer. And if Teledyne FLIR decides to replace them for functional reasons, the aluminium can always be recycled. There is an established recycling process in place worldwide, making aluminium a clearly sustainable choice.

Tens of thousands of aluminium housings have been produced since 2012 and Teledyne FLIR is well-satisfied. Pedeo also produces several other aluminium cameras for Teledyne FLIR, for both visual and thermal imaging.

Pedeo will take a customised approach to your project as well. We will select the most appropriate material and optimise the design, project and process steps. Every project comes with its own reasons to opt for a specific material, and the advantages of a casting in aluminium or Zamak will be different in each case.

What advantages can aluminium or Zamak offer your high-pressure die-cast items?

Come and visit our stand and challenge us with your projects on 15 and 16 September 2021 at the Kunststoffenbeurs 2021 in ’s Hertogenbosch.

Apply for your free entrance ticket here.