Raw materials cost a fortune these days, and there is no immediate improvement yet in sight. High-pressure die casting uses our raw materials sustainably, reducing costs as a result.

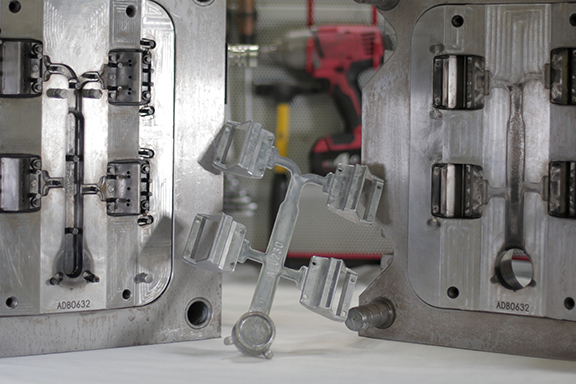

Maximum functionality with minimum material

By its nature, high-pressure die casting, which makes light components and thin walls possible, is a technique that saves on raw materials. A cleverly chosen geometry guarantees strength and avoids superfluous solid areas.

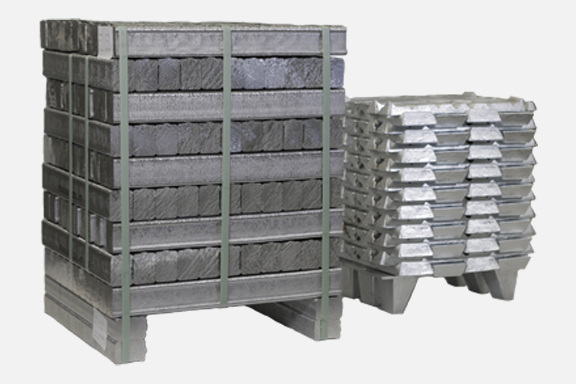

Nothing is lost

A casting that has just come out of the die still contains the feeding channels. These are removed and immediately reused so that this material is not lost.

Only pay for what you receive

Forming techniques that are carried out using machining start out with a solid block and then remove material to achieve the desired shape. With high-pressure die casting however, you only pay for the material that is actually present in the casting.

For your product as well

We’re sure that you too are feeling the impact of rising raw materials prices. We can design and manufacture your components in an economic and sustainable manner.