Quality and sustainability

Quality management

From the very beginning, Pedeo has invested in quality. Pedeo obtained its first ISO certificate in 1992.

It was not an end point, but the basis on which Pedeo has further developed its internal quality system to ensure reliable production.

Quality plan

Each project is accompanied by a quality plan, containing which controls are used and how and how often these are carried out during the production process.

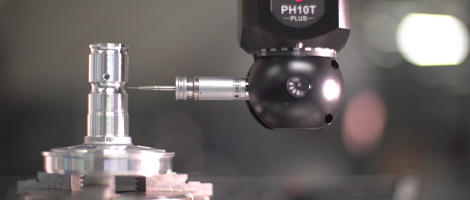

Pedeo has a climate-controlled lab with 3D measuring machines and other calibrated measuring instruments.

Process monitoring

In addition to these controls, the critical process parameters are also monitored. The output is processed automatically and processes are adjusted if necessary.

Traceability

Pedeo has various options for guaranteeing the traceability of parts:

- Label with batch number and serial date

- Embedded date stamp

- Engraving of date and time of production

- Laser marking of e.g. QR codes

Sustainability

Sustainability is an important aspect to which Pedeo is strongly committed. Zinc and aluminium alloys have the advantage that they are perfectly recyclable and that the material can be reused many times. All alloys used by Pedeo comply with the provisions of RoHS, REACH and ELV.

By continuously improving production processes, Pedeo strives to reduce its CO2 emissions and ecological footprint constantly. The 100% electric smelting furnaces are a good example of this.

Safety

A healthy, safe and dynamic working environment is an important key to success.

On the one hand, training on safety and ergonomics, on the other hand, active communication on safety regulations and risks; both are important elements for achieving this. Combined with a number of control mechanisms within the daily processes, this all makes safety a natural reflex for all employees.